| Color: | |

|---|---|

| Size: | |

| system: | |

| Availability: | |

| Quantity: | |

Y32-315T

JIANHA

Certificate

Servo Motor

1、Excellent sealing and pressure-holding performance

Fan Blade Retainer

Fan housing

Fan blades

Fan

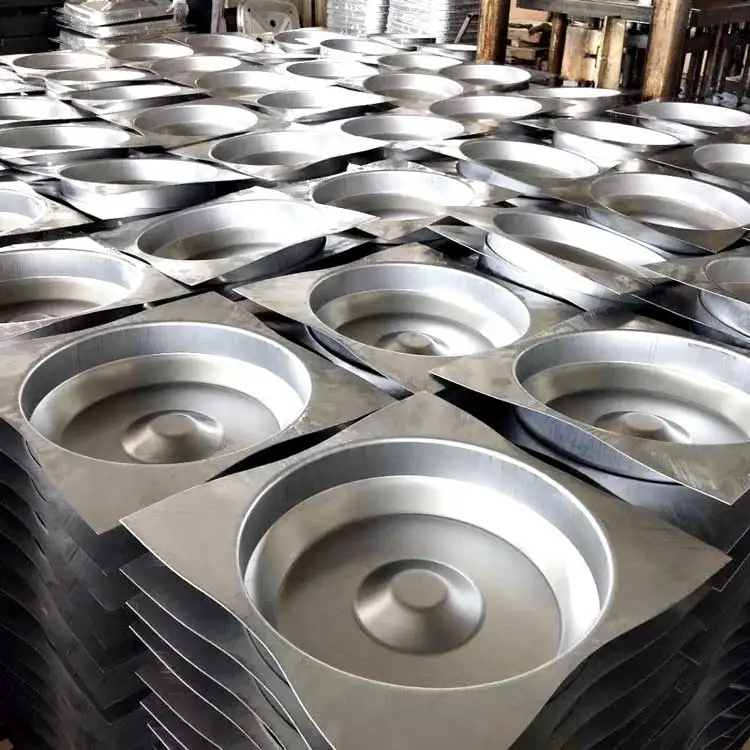

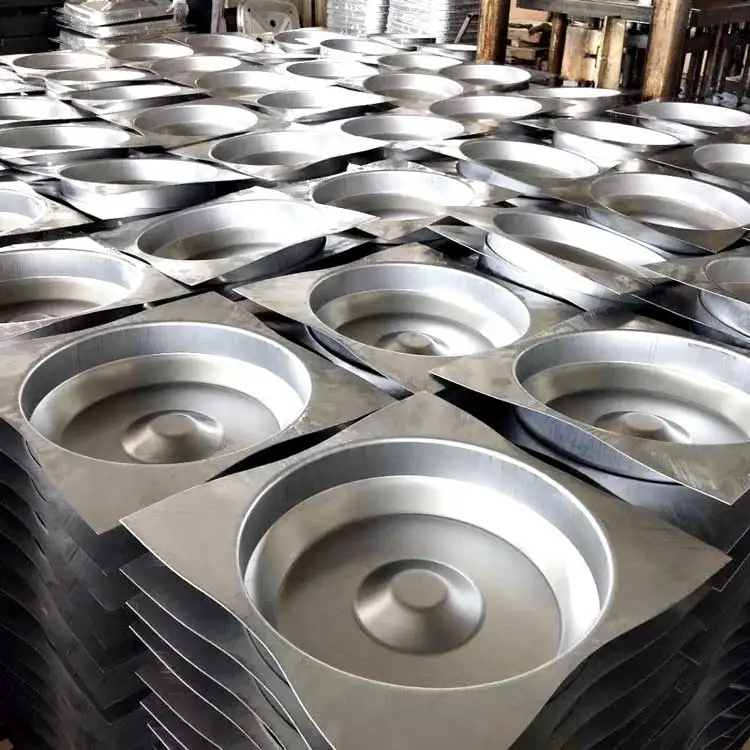

Fan This series of machine tools suitable for shallow drawing, flanging, forming, and other operations, the lower top cylinder provides uniform pressing force to prevent wrinkling of the sheet metal.Hydraulic presses are equipped with electronic hydraulic directional control valves or cartridge valves, featuring compact structure, safety and reliability, sensitive operation, high speed, low energy consumption, and low noise.

| Provide a full-process production line |

| One-year warranty |

| On-site Installation Service |

| 24-hour online consultation service |

Shandong Baofa Intelligent Heavy Industry Machinery Co., Ltd. is located in Tengzhou City, Shandong Province, China, which is a leading center for hydraulic press manufacturing in China. It was established in 1996,has a factory area of over 7,000 square meters, with fixed assets exceeding 30.1 million yuan and a staff of over 106 people, including 36 R&D technicians. We firmly believe that only by constantly innovating can enterprises achieve sustainable development; and only by grasping the needs of customers can they lead the industry trend.

A:Hydraulic presses, die casting machines, CNC machine tools, wheel axle machines, etc.

A:If you have specific requirements for the machine, please tell me the tonnage, opening, stroke, workbench size, etc.;

Q:Why choose us?

A:1. Exports to over 60 countries annually, recognized by governments worldwide

2. Possesses R&D capabilities, inspectors, and specialized technical personnel

3. Features dedicated pre-sales, sales, and after-sales service teams providing one-stop solutions

4. Offers customized products with on-site installation services

Certificate

Servo Motor

1、Excellent sealing and pressure-holding performance

Fan Blade Retainer

Fan housing

Fan blades

Fan

Fan This series of machine tools suitable for shallow drawing, flanging, forming, and other operations, the lower top cylinder provides uniform pressing force to prevent wrinkling of the sheet metal.Hydraulic presses are equipped with electronic hydraulic directional control valves or cartridge valves, featuring compact structure, safety and reliability, sensitive operation, high speed, low energy consumption, and low noise.

| Provide a full-process production line |

| One-year warranty |

| On-site Installation Service |

| 24-hour online consultation service |

Shandong Baofa Intelligent Heavy Industry Machinery Co., Ltd. is located in Tengzhou City, Shandong Province, China, which is a leading center for hydraulic press manufacturing in China. It was established in 1996,has a factory area of over 7,000 square meters, with fixed assets exceeding 30.1 million yuan and a staff of over 106 people, including 36 R&D technicians. We firmly believe that only by constantly innovating can enterprises achieve sustainable development; and only by grasping the needs of customers can they lead the industry trend.

A:Hydraulic presses, die casting machines, CNC machine tools, wheel axle machines, etc.

A:If you have specific requirements for the machine, please tell me the tonnage, opening, stroke, workbench size, etc.;

Q:Why choose us?

A:1. Exports to over 60 countries annually, recognized by governments worldwide

2. Possesses R&D capabilities, inspectors, and specialized technical personnel

3. Features dedicated pre-sales, sales, and after-sales service teams providing one-stop solutions

4. Offers customized products with on-site installation services

On-site installation in Italy -----The customer was very satisfied with the engineers and installers

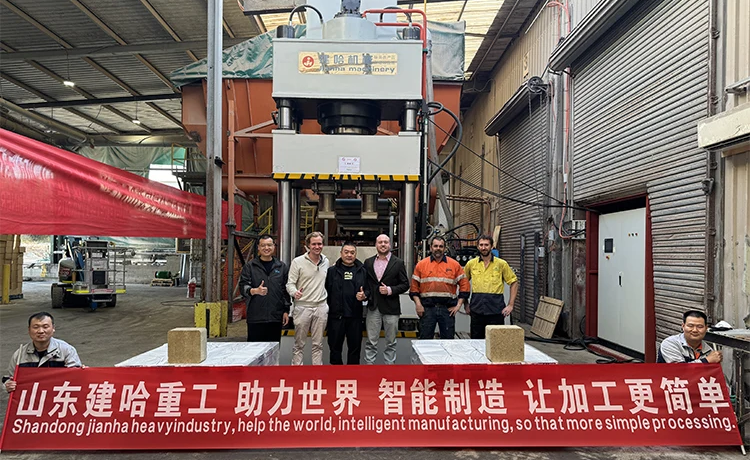

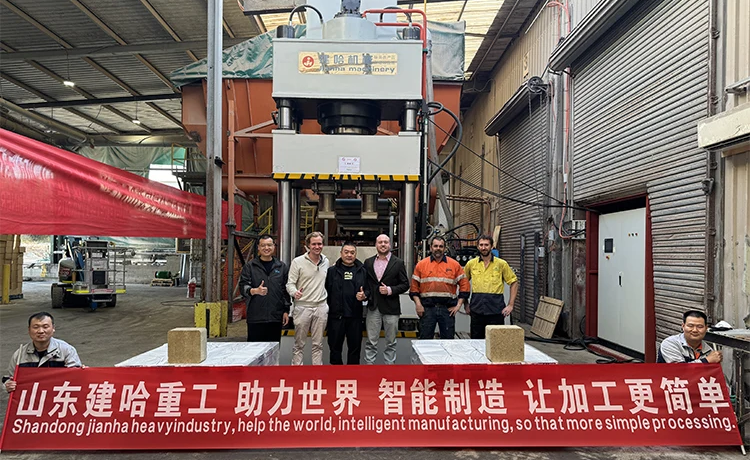

International partners visit the factory for inspections and technical discussions

Customers conduct machine inspections prior to shipment

On-site installation in Italy -----The customer was very satisfied with the engineers and installers

International partners visit the factory for inspections and technical discussions

Customers conduct machine inspections prior to shipment